Applying digital technology in enhancing the competitiveness of industrial production enterprises

The rapid and comprehensive explosion of technology in general or digital technology in particular for digital transformation has brought about diverse choices but also potential risks and challenges in the application process. Therefore, understanding, evaluating and choosing appropriate and effective technology is the most important task in the digital transformation process of businesses and organizations.

The demand of the market is always the reason for manufacturers to change, improve, to innovate and that is also the challenge for modern industrial production. In response to the requirement, it is necessary to quickly provide products with powerful, multi-use, smarter features, or the ability to customize according to individual needs, better designs, etc., while still ensuring the integrity of the product. seamless connection, multi-layer security but easy experience, industrial manufacturers have had to spend a lot of resources on research and development activities. The tremendous growth of the US companies Facebook, Amazon, Google, Samsung of Korea, Ant Group (China) or the decline in market share of Toshiba, Sony or the disappearance of Nokia, Windows Phone… or the emergence of The appearance of the Vietnamese car brand, Vinfast, on the world map of the auto industry is proof that technology not only plays a role in leading the development of society, the development of economic sectors. and strongly influence people’s thoughts, views and consumption habits, but technology also plays a decisive role in the existence and development of any business or organization.

Which option for industrial production enterprises

In the face of market changes, technology firms around the world have quickly researched and introduced new technology tools and solutions capable of predictive analysis, synchronous connectivity, and information provision. in real time… to support the process of analysis, assessment, management and operation of production and business activities, thereby saving time and costs, improving the working efficiency of individuals, completing improve corporate governance of the organization. Concepts intelligent manufacturing, digital factory, systems of systems, additive manufacturing, edge computing, advanced robotics, cloud technology, digital cloning, artificial intelligence, big data… has quickly become an application trend in industrial production with the ability to transform production models, turn ideas into actual products quickly and accurately, and also change the presence of products. the product on the market most unexpectedly. Smart manufacturing is the application and integration of the latest technologies today, from industrial connection of things (IioT), artificial intelligence (AI), virtualization (Virtual), cloud computing ( Cloud Computing)… on a synchronous and unified platform. Technology can be applied throughout from product design and development (CAD), pre-production evaluation simulation (CAE) to production into product (CAM)… to management. after-sales service (Service) when the product is put into use. These are the first steps of the transformation from a traditional manufacturing enterprise model to a digital factory model. Vinfast is a typical enterprise that has achieved success when effectively applying technology in design, management and production activities to quickly supply a variety of cars to the market in less than 2 years. from the date of commencement of the production plant in Hai Phong.

The rapid and comprehensive explosion of technology in general or digital technology in particular for digital transformation has brought about diverse choices but also many potential risks and challenges in the application process. Therefore, understanding, evaluating and choosing appropriate and effective technology is the most important task in the digital transformation process of businesses and organizations. According to the experience of countries with developed industries in the world, the trend of digital technology application in industrial production companies is usually divided into two main industries: discrete manufacturing industry ( discrete) and mass production by process.

With the discrete manufacturing industry, which produces single products or complex products, with high customization capabilities, businesses often apply technology to increase overall work efficiency, maximize productivity. automation, increasing the synchronous connection of input and output systems. Often technology is applied in the following stages:

- New product research and development (R&D) phase

- Stage of technical design, analysis and evaluation of design optimization (Design and Simulation)

- Simulate device product evaluation

- Product Data Management (PDM)

- Production stage

- Automated production planning (Planning and Scheduling)

- Warehouse and Supply Chain Management (Warehouse and Logistics)

- Customer Database Administration (CRM)

- Manufacturing Operations Management (MES)

- Service Management (Service Management)

- Enterprise Resource Management (ERP)

- Product lifecycle management (PLM)…

- Factory Digitization (Smart Factory)

For businesses operating in the field of mass production in large quantities such as beverage production, consumer goods, etc., they are interested in digitization in the stages of quality management, change management, and production planning. production, warehouse and supply chain management (Supplier Management), customer relationship management (CRM), resource management (ERP), production management (MES), …

Regardless of the stage of the application of digital technology in the production process, most businesses follow the production value chain, thereby determining development strategies, forming the need for improvement, change, and planning. determine the necessary resources… to develop an appropriate digital transformation roadmap and plan, in order to ensure that the goals of quality improvement, new and better products are achieved, more cost-effective, and work efficiency is achieved. higher, improve labor productivity, increase competitive advantage.

The journey of manufacturing enterprises to industry 4.0

Developing smart production and implementing digital transformation has become an inevitable trend of enterprises in the context of the 4th Industrial Revolution. This is even more evident when competition among businesses is increasing day by day. With a fierce, risk factors, more and more uncertainty, businesses have to constantly innovate and adapt to develop.

However, most industrial manufacturing enterprises are at a low starting point on the way to the final destination of a digital enterprise smart manufacturing enterprise. The evaluation results of the Ministry of Industry and Trade show that the application level of key technologies from the 4th Industrial Revolution by industrial production enterprises is still very limited, such as 3D printing technology, wave identification. radio, Big Data is only 2%; 3% with Artificial Intelligence, Real-time Positioning etc… Cloud computing software has the most enterprise application level, 15%, but the level of exploitation and use of this software is also very different. at businesses. Survey results show that: 22% of businesses use data storage services, 17% of businesses use cloud-based software, only 5% of businesses say they use data analysis services. Whether. Data-based corporate governance models have a very limited adoption rate, only around 5%. For example, systems of Supply Chain Management (SCM), Product Lifecycle Management (PLM), Production Planning System (PPS), Product Data Management (PDM) etc. the level of adoption is only at 2-3%. In addition, the ability to digitize data and connect data within the enterprise as well as between the enterprise and its partners in the chain is still very limited; This leads to a very low ability to self-operate according to changes and automatically manage the enterprise, at only 2% (at the enterprise-wide scale); 11-12% (in individual areas of the business).

With the main destination of Industry 4.0, the main focus is on 4.0 businesses, digital businesses, each business needs to choose a suitable journey based on (1) the current capacity of the business. compared to the requirements of smart industrial development; (2) current priorities or challenges for business development and (3) effectiveness. Investing in technology innovation and digital transformation will be an investment in new values and competitiveness of businesses. This roadmap will largely depend on the strategy and vision of the enterprise in a new development context.

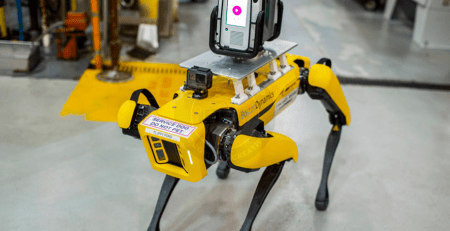

ITDC’s cargo sorting robot belongs to IDEA corporationResolution 52-NQ/TW of September 27, 2019 of the Politburo expresses the Party’s cross-cutting views on the undertakings and policies to actively participate in the Fourth Industrial Revolution, with particular emphasis on issues of supporting businesses in digital transformation and smart production development. Concretizing the Party’s orientation, assigning tasks of the Government, currently, the Industry and Trade sector is actively participating. Establishing fundamental factors, creating a favorable environment for businesses to develop, apply science and technology and innovate, quickly take advantage of opportunities from the Fourth Industrial Revolution onward. become one of the priority solutions to carry out the priority tasks of the industry and trade as well as the goal of improving the position and competitiveness of each enterprise.

Ms. Dam Thi Hong Lan – Director of Vietbay Technology Co., Ltd