What are the advantages and disadvantages of automating production lines? Purpose and case studies

In the recent manufacturing industry, problems due to soaring labor costs and human troubles are becoming more serious. In this trend, the automation of the production line has become so important that it can be said that it is indispensable. So this time

- We are considering automating the production line

- I want to improve production efficiency

- I want to know the case

We will answer your questions.

If you are considering automating your production line, or are curious about the current state of automation, we hope you will find it helpful. Automate your production line

- I want to reduce costs by saving labor and manpower.

- Increase productivity and increase sales

- I want to reduce human error and increase quality value

- I don’t know which manufacturer’s device or robot should be used for efficiency

1. Why more and more companies are automating their production lines

Companies that feel the importance of automating their production lines are already working towards automation.

The importance of automation has been talked about for a long time, but why has it started to attract more attention recently, and more and more companies are introducing it? The reason is

- Soaring labor costs both in Japan and overseas

- chronic labor shortage

- Productivity review

I can give you something like this.

Until now, the flow of manufacturing has maintained productivity by hiring a large number of workers at low wages.

However, recently, labor costs have risen even overseas, and the current situation is that it is no longer possible to use the same production methods as before.

In addition, due to the diversity of work styles, labor shortages are occurring at every factory. It is clear that this trend will continue to grow.

Then, no matter how much you want to produce it at the factory, you will be in a situation where you can’t.

Therefore, the automation of production lines has become a focus of attention.

2. Purpose of automating the production line

Introduce the purpose of automating the production line.

(1) Maximize profits by improving productivity and stabilizing quality

I think the purpose of automating the production line will differ depending on the company.

However, they all have one thing in common: maximizing profits.

By automating the production line, you can expect “improved productivity” and “stability of quality”.

Ultimately, automating production equipment should be considered by any company, as it will ultimately lead to profits.

(2) Eliminate the negative factors of 4M (people, machines, materials, methods)

In production, “productivity” and “quality” are greatly related to the following things called “4M” of manufacturing.

- Man: Worker/human factor

- Machine: Factors related to machinery and equipment

- Material: Factors related to raw materials

- Method: Work method and factors related to method

These 4Ms are a factor in all productivity and troubles related to manufacturing.

Recently, “Media: Causes related to information”, “Management: Causes related to management”, and “Environment: Causes related to environmental changes” have been added to the term “6M1E”, but the above 4Ms are becoming more important.

Above all, “Man: Worker/Human factors” is the most important part of 4M. Because it’s all about other 3M.

By automating the “workers” who are related to all factors to “robots”, in other words, by automating the production line, it will lead to improvements in productivity and quality.

3. Benefits of automating production lines

That said, I think it’s hard to imagine in concrete terms what benefits there are in automating the production line.

So, I will explain the merits of automating the production line.

The advantages of automating the production line are:

- Increased productivity

- Stable quality

- Elimination of unspecified factors

- Reduced labor costs

I can give you something like this.

(1) Improving productivity

Humans cannot work 24 hours a day.

Of course, you can continue to work in shifts, but there are still limits.

Robots can operate 24 hours a day, 365 days a year. In addition, because they can work faster than humans, the number of production increases dramatically.

As an example, there are cases in which equipment that has automated production lines has increased production volume by three times, even though the number of workers has been reduced to one-third.

(2) Stable product quality

Even if it is the same process,

- Worker proficiency

- physical condition of the worker

Due to human factors such as, there will be variations in product quality and production numbers.

With a robot, it is possible to maintain a constant level of quality no matter who operates it.

(3) It is easy to identify the cause, and it is possible to improve smoothly.

Variation occurs due to various factors until the product is completed.

Of course, there are times when defective products are produced due to human error. As human beings, this is inevitable.

At present, it is difficult to deal with or improve these human errors because they are so vague that the work was not accurate due to lack of sleep, or that there was a problem with the production method in the first place.

Automating the production line makes it easier to identify the cause of defective products and troubles. Also, if you look at the data, it will be easier to find problems, so you will be able to improve them immediately.

(4) Leads to reduced labor costs

By automating the production line, labor costs can be greatly reduced.

We can reduce the number of workers required for the entire factory, and it is also possible to reduce the sudden cost of securing the necessary human resources when workers suddenly quit.

4. Example of improvement by introducing automation of the production line

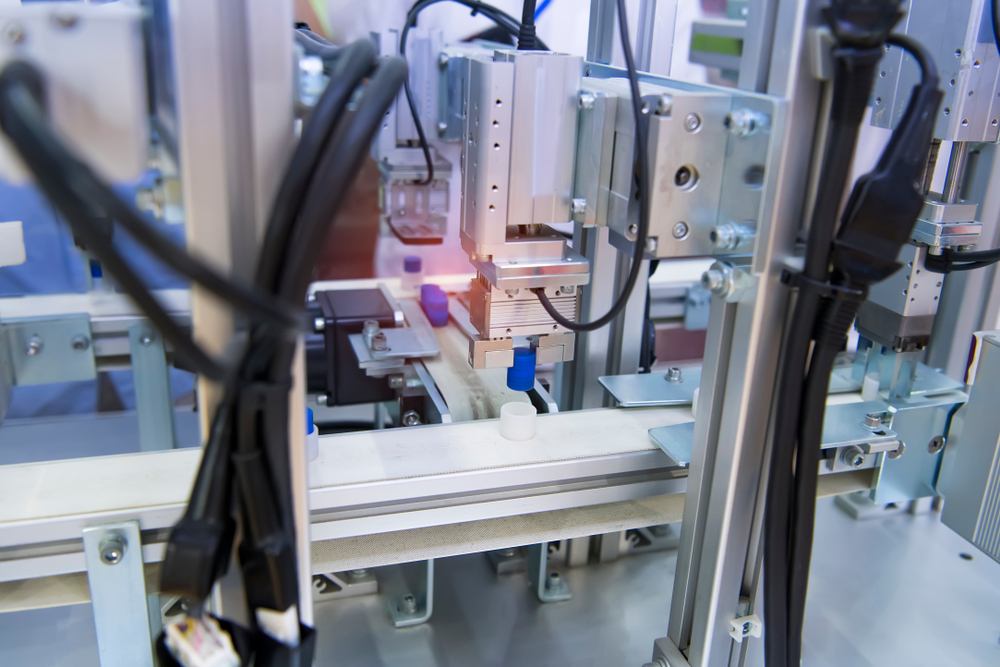

※The image is an image.

| Product Name | Delivery destination | Usage | Realized | Technology used |

| Auto parts assembly equipment | automotive industry | Labor saving and labor saving | Achieved labor saving by machine. Prevents variations in products that would occur if done manually. | ・Z-fold The workpiece is mountain-folded and valley-folded for storage. Advanced technology is used to neatly fold one piece of work. ・Automatic elevator Adjust height. It can be adjusted according to the height of the worker. ・Human-friendly device Since it is a joint work between the device and the person, it is adjusted so that it does not hurt even if the hand is caught. ・Automatic speed adjustment Since it is folded while rolling, the warp expands. If the winding is too fast, the workpiece will tear, and if the winding is too slow, To prevent this, we adjust the speed at which the robot descends and its rotation speed. Established coordination between rotation speed and processing speed with PLC. ・Support for various types of jigs Workpieces can be removed and attached with a single touch. |

※The image is an image.

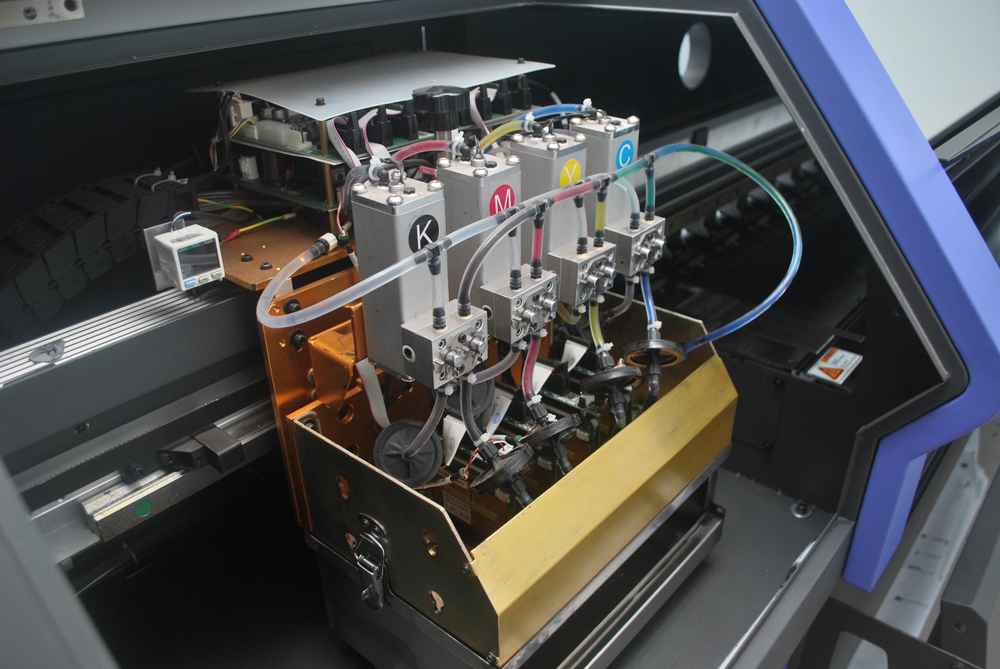

| Product Name | Delivery destination | Usage | Realized | Technology used |

| Assembling the heads of industrial inkjet printers | OA equipment industry | labor saving | Apply glue automatically using XYZ. As a result, the application position and application amount can be stabilized, saving labor. | ・XYZ robot The application position can be specified as desired. I am doing PLC control. ・Adhesive application system Quantitative application is realized. UV and adhesive can be applied with one device. ・Shutter for UV irradiation If you see it with your eyes, you may lose your eyesight, so we set up a shutter to prevent the UV from leaking outside. ・Clean before applying adhesive Adhesive may clog the tip of the needle if it is not cleaned. Therefore, it is always cleaned and then applied, achieving a fixed amount of application. ・Installation of area center Safely designed to stop when a person enters the retracted position |

5. Issues and disadvantages of automating production lines

Automating your production line has many benefits. However, automation still has its challenges and disadvantages.

So, let’s consider whether to introduce automation depending on the situation and purpose of your company.

This time, I will introduce the disadvantages and issues that can be considered when introducing automation of the production line.

(1) High introduction cost

The biggest problem in automating the production line is the cost at the time of introduction.

- Training and employment of engineers

- Coordination with related line equipment

- Ensuring safety

In addition to introducing robots, there are other costs involved.

In automating the production line, we have to calculate all the necessary costs.

Having said that, it is a wise choice to have an estimate, as it is not possible to calculate even a rough estimate without first knowing how much it will cost to introduce a robot.

(2) Unmanned operation is difficult

Even if the production line is automated, the current situation is that it is difficult to make it completely unmanned.

- Robot adjustment

- Maintenance management

- Human work in detail

It may be difficult to automate the parts that absolutely require workers, such as the above.

However, it is not 100% impossible, so if there is a part you want to automate, it is a good idea to consult with us once.

(3) We need excellent human resources

The introduction of robots will eliminate the need for human resources as workers.

However, after introducing a new robot, we need human resources who can “operate and manage” it.

You can train them in-house, hire them, or outsource them.

No matter what you choose, you’ll need new talent, so keep that in mind.